Product Description

HIPS Sheets

Being a noteworthy name in exporting and trading a quality assured range of HIPS Plastic Sheets that is used in food, dairy and medical packaging industries. These sheets are manufactured using the best grade high impact polystyrenein and advanced techniques in adherence with set global market standards under our vendors' guidance. Offered High Impact Polystyrenein Plastic Sheets are quality assured by our vendors on various quality benchmarks to ensure a flawless product delivery.

Features:

- Easy formability

- Durability to temperatures as low as -20F

- Sterilization by ETO, gamma, or electron beam

- No corrosive or noxious fumes

- 100% recyclable

Specifications: - Styrene is available in standard 48" x 96" sheets, or customer Sheets & Rolls

- Also available in Conductive Grades upon request.

|

| Units | ASTM Test Method | Values |

| Strength to Weight Ratio | ksi | - | 3.8 |

| Specific Gravity @73 F | - | D792 | 1.04 |

| Tensile Strength @73 F, (ult)/(yld) | psi | D638 | 4000 (ult) |

| Tensile Modulus of Elasticity @ 73 F | psi | D638 | - |

| Tensile Elongation at Break @ 73 F | % | D638 | 50 |

| Flexural Strength @ 73 F | psi | D790 | - |

| Flexural Modulus of Elasticity @ 73 F | psi | D790 | 260000 |

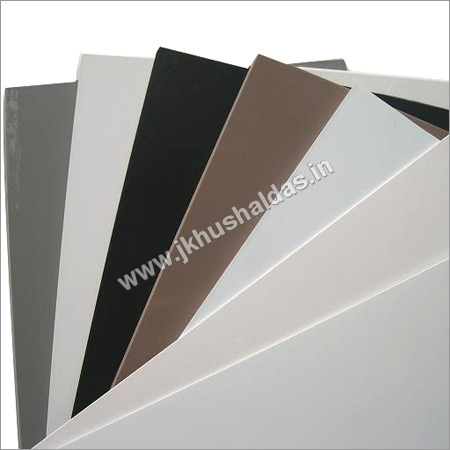

Versatile Surface FinishesAvailable in smooth, glossy, and matte finishes, HIPS sheets adapt to any project requirementwhether for visual appeal in displays or functional applications in packaging.

Customized DimensionsChoose from standard sheet sizes up to 1220 mm wide and 2440 mm long, or request custom sizing to fit unique specifications for your projects.

Robust Temperature ResistanceEngineered to withstand temperatures up to 80C, these sheets maintain structural integrity in a range of environments, making them suitable for demanding thermoforming processes.

Applications Across IndustriesHIPS sheets are widely used in thermoforming, packaging, displays, and even automotive interiors, thanks to their high impact strength, low water absorption, and versatility in shaping and processing.

FAQs of HIPS Sheets:

Q: How are HIPS sheets processed for various applications?

A: HIPS sheets can be processed using thermoforming, vacuum forming, cutting, and extrusion methods. These flexible techniques allow the sheets to be shaped, molded, or trimmed according to specific project requirements.

Q: What are the benefits of choosing HIPS sheets for packaging and displays?

A: HIPS sheets offer high impact strength, low water absorption, and customizable finishes. Their durability and visual appeal make them excellent choices for both packaging and display solutions.

Q: When should I consider using HIPS sheets for my project?

A: Consider HIPS sheets if your application requires high impact resistance, good temperature tolerance (up to 80C), and flexibility in sheet sizes and surface finishes. They are particularly suitable for thermoforming, packaging, and automotive interiors.

Q: Where are these HIPS sheets typically used?

A: These sheets are commonly used in industries such as automotive (for interiors), packaging, retail displays, and other sectors where durable, formable plastic sheets are essential.

Q: What processing methods can be applied to HIPS sheets?

A: HIPS sheets support various processing methods, including thermoforming, vacuum forming, and cutting, allowing for a wide array of shapes and designs to meet application needs.

Q: How does the low water absorption of HIPS sheets benefit their usage?

A: Low water absorption ensures that HIPS sheets maintain their structural integrity and appearance even in humid or moist environments, making them ideal for packaging, automotive, and display applications.